We solve specific requirements for the processing of semi-finished products!

Is it difficult to find a partner for your specific requirements for the processing of semi-finished products (cutting and bending, making of bores, proper protection of the product-galvanization/dying)?

Do you need advice on product development itself and in finding the optimal solutions for making?

Do you appreciate a partner who provides the highest possible quality to its customers?

Sico d.o.o. provides all that … and more!

Is it possible to produce a piece with the correct dimensions in the first attempt?

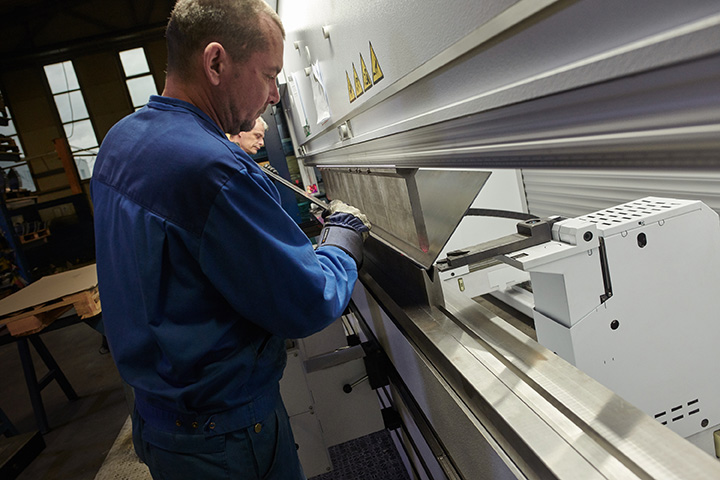

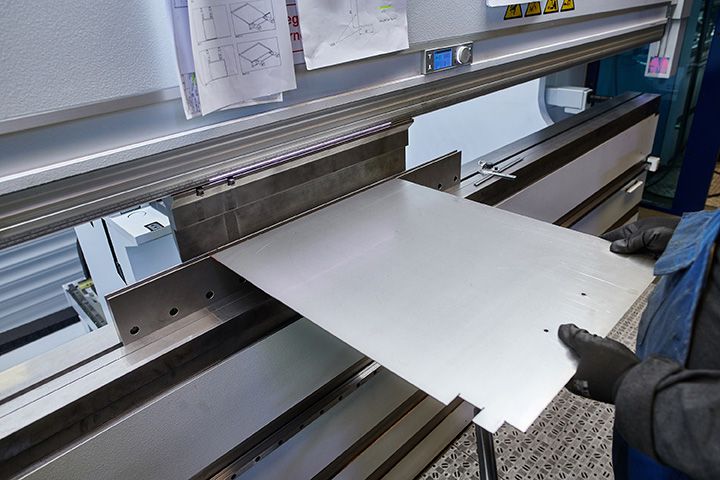

All of our bending machines are CNC controlled (controlled axes, robotic tool feeder, robot service), they have sensor angle measurement with an angle accuracy of 0.5° and allow us to

produce a good piece on the first try. This ensures that the piece that comes out of the bend is made in the right dimensions, and the final dimensions are within the desired tolerances.

Possible bending lengths:

- 0,5 – 5 mm = 4000 mm

- 6 mm = 3600 mm

- 8 mm = 3000 mm

- 10 mm = 2000 mm

- 12 mm = 2000 mm

Possible bending radii:

R0.5/ R1/R3/R4/R8/R10/R15/R20/R25

The largest permanent stock of various materials – more than 500 tons of sheet metal up to a thickness of 30 mm.

Advantages of the machines that are used in bending of the material:

BENDING OF MATERIAL 230 tons up to thickness of 12mm.

- Trumpf V85 CNC bending 85 tons/2000 mm;

- Trumpf V230 CNC bending 230 tons/3000 mm;

- Trumpf V5230S CNC bending 230 tons/4000 mm 6-axis CNC control, the possibility of making several types of shapes.

PRESSING up to a thickness of 2.5 mm and a length of 4000 mm.

Why work with us?

1. Consulting

At Sico d.o.o. we have many years of experience and a high level of knowledge so we can provide our customers with top-level advice in the development of the product and help them find the best ways to manufacture. We help our customers with providing the best solutions at the lowest cost.

2. Resolving special bending requirements

Continuous education, participation in trade shows, years of experience as well as investments in modern equipment enable us to offer our customers the most specific requirements in the field of bending.

Do you have special bending requirements? Sico d.o.o. has solutions!

3. Quality

The cutting-edge hardware we use, enables us to bend the faultless quality with correct final dimensions in the first attempt.

Sico d.o.o. – Quality at the highest level!

4. All solutions in one place

With the help of our proven subcontractors, we provide our customers with comprehensive solutions in one place. Thus, we make sure that the product is cut and bent, that bores are made and that the product is properly protected in the end – galvanized or dyed.

What we cannot do alone, we can do with the help of our tested subcontractors, which we supervise in accordance with the established standard ISO 9001:2015.